The new SD-26 Type S sliding head lathe is an entirely new model capable of ⌀26mm machining that has been developed by Star to give engineers the ultimate mill-turn solution for complex components.

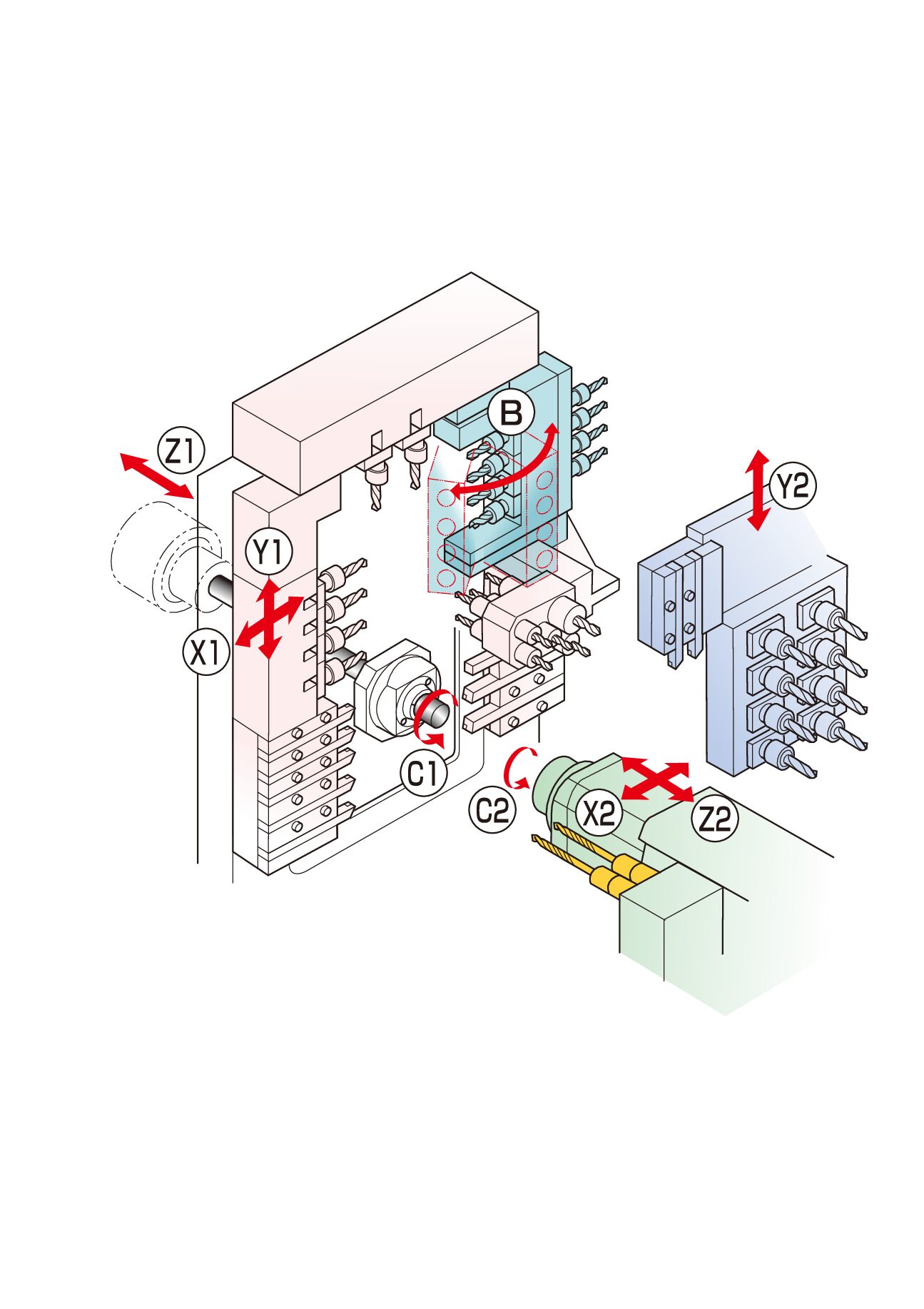

The Type S variant offers Star’s patent-pending twin B-axis programmable heads, where B1 has 4 front and 4 rear tools and B2 offers an interchangeable cartridge station. This station can accept twin mill drill spindles providing 6 spindles in total for angular features, or a double threading whirling attachment for complex bone screw manufacture, or a twin sleeve holder for high-speed electronic spindles for complex 3D 5-axis profile milling.

The SD-26 Type S is extremely configurable with numerous cartridge positions to mount various tooling attachments for complex work pieces. The ergonomic design with back working tool post to the rear of the cutting room allows easy access for swift changeovers and more room for automation to extract parts.

Reviews

There are no reviews yet.